Chemical Composition:

MuMETAL® Chemical Composition % In Weight*

Nickel (Ni) 80-82%

Molybdenum (Mo) 3.5-6%

Manganese (Mn) 0.8% max

Silicon (Si) 0.5% max

Cobalt 0.5% max

Copper 0.30% max

Chromium 0.30% max

Phosphorus 0.02% max

Sulfur 0.01% max

Carbon (C) 0.05% max

Iron (Fe) Balance

*Composition may vary by production lot.

Nickel (Ni) 80-82%

Molybdenum (Mo) 3.5-6%

Manganese (Mn) 0.8% max

Silicon (Si) 0.5% max

Cobalt 0.5% max

Copper 0.30% max

Chromium 0.30% max

Phosphorus 0.02% max

Sulfur 0.01% max

Carbon (C) 0.05% max

Iron (Fe) Balance

*Composition may vary by production lot.

| mumetal_stress_annealed_sheet_data.pdf | |

| File Size: | 193 kb |

| File Type: | |

| mumetal_fully_annealed_foil_data.pdf | |

| File Size: | 180 kb |

| File Type: | |

| mumetal_round_bar_data.pdf | |

| File Size: | 226 kb |

| File Type: | |

| machining_mumetal.pdf | |

| File Size: | 137 kb |

| File Type: | |

Material Properties:

|

TYPICAL PHYSICAL PROPERTIES*

Density : 0.316 lb/in³ [8.7g/cm³] Melting Temp : 2642°F [1450°C] Curie Temp : 788°F [420°C] Resistivity : 60 μΩcm Thermal Conduction : 19 (W/°Km) Specific Heat : 460 (J.Kg-¹ .°K-¹) TYPICAL MECHANICAL PROPERTIES* Stress Annealed Properties Hardness : 160 Hv Tensile Strength : 700 MPa 0.2 % Yield Strength : 280 MPa Elongation : 45 % Grain Size: 6-8 Final Annealed Properties Hardness : <120 Hv Tensile Strength : 530 MPa 0.2 % Yield Strength : 160 MPa Elongation : 32 % Grain Size: 0-3 *Data for each material thickness and/or lot may vary. |

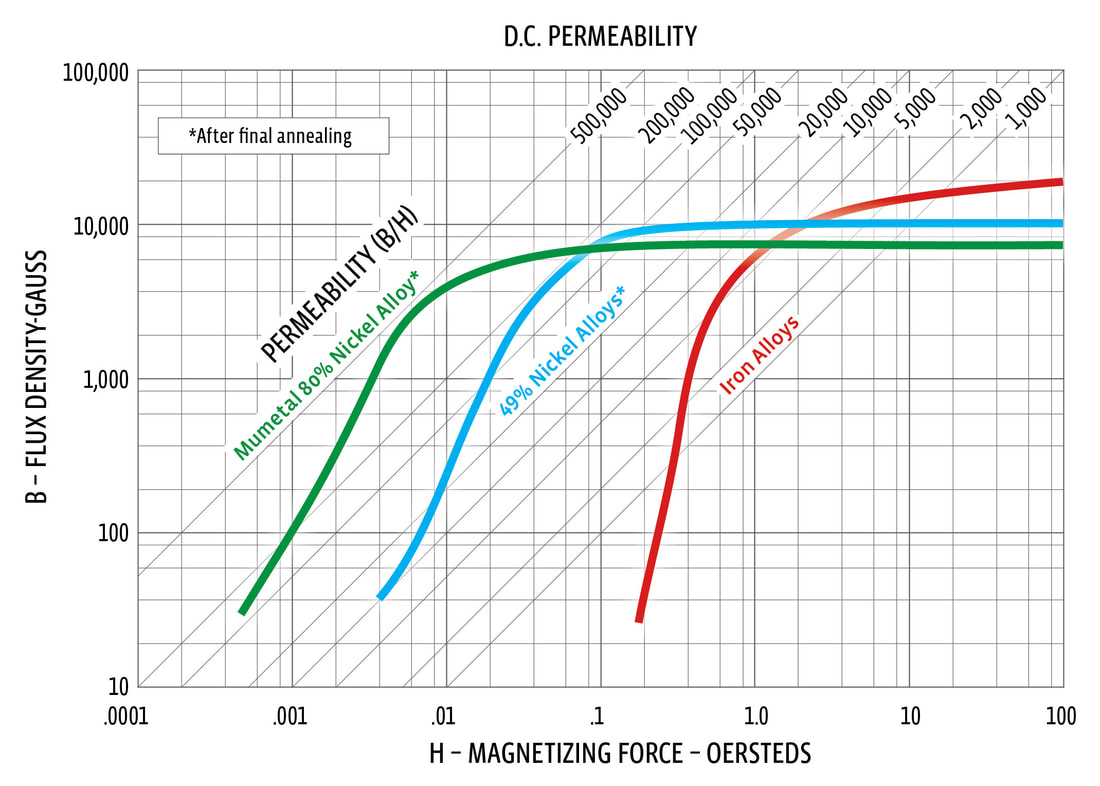

TYPICAL MAGNETIC PROPERTIES*

DC μ @ 40 gauss 80,000 DC μ @ 100 gauss 105,000 DC μ maximum >400,000 DC Hc <0.007 Oe [0.6 A/m] DC Br (gauss) 4,000 DC Bs (gauss) 7,600 AC 60Hz μ @ 40 gauss 65,000 *Data are typical of .014" [0,36mm] final annealed sample and should not be construed as maximum or minimum values for specification or final design. Data for each material thickness and/or lot may vary. |

B-H Curve:

*Data are typical of .014" [0,36mm] final annealed sample and should not be construed as maximum or minimum values for specification or final design. Data for each material thickness and/or lot may vary.

For spreadsheet versions of our BH curve, please contact us.

For more technical information on soft magnetic nickel-iron alloys visit our full website here

For more technical information on soft magnetic nickel-iron alloys visit our full website here