What is magnetic permeability?

μ (Mu) – The 12th letter of the Greek alphabet, is used in physics and engineering formulae to represent permeability, the measure of a material’s ability to support the formation, or absorption, of a magnetic field within itself. In other words, permeability (μ) is a value representing the degree of magnetization obtained in a material from an externally applied H-field. MuMetal is a soft ferromagnetic alloy (a.k.a. magnetically soft), with a high nickel content, which means that it does not retain a field after the removal of an external magnetizing force. Because our alloy provides maximum permeability in magnetic shielding, it has been permanently named after the Greek letter μ (Mu). Permeability is measured by calculating the ratio of the magnetic flux density, B (Tesla) in the material to the magnet field strength, H (A/m):

µ = B/H

Relative permeability, µr is this ratio divided by the permeability of free space which is 1.257E-6

Does MuMetal block magnetic fields?

MuMetal re-directs magnetic flux so it lessens the magnetic field’s influence on the item being shielded. Shielding does not eliminate or destroy magnetic fields, nothing does. It does, however, provide an easy path for the magnetic field to complete its path. You may think of it as a magnetic field conductor or shunt.

Does MuMetal provide shielding at radio frequencies?

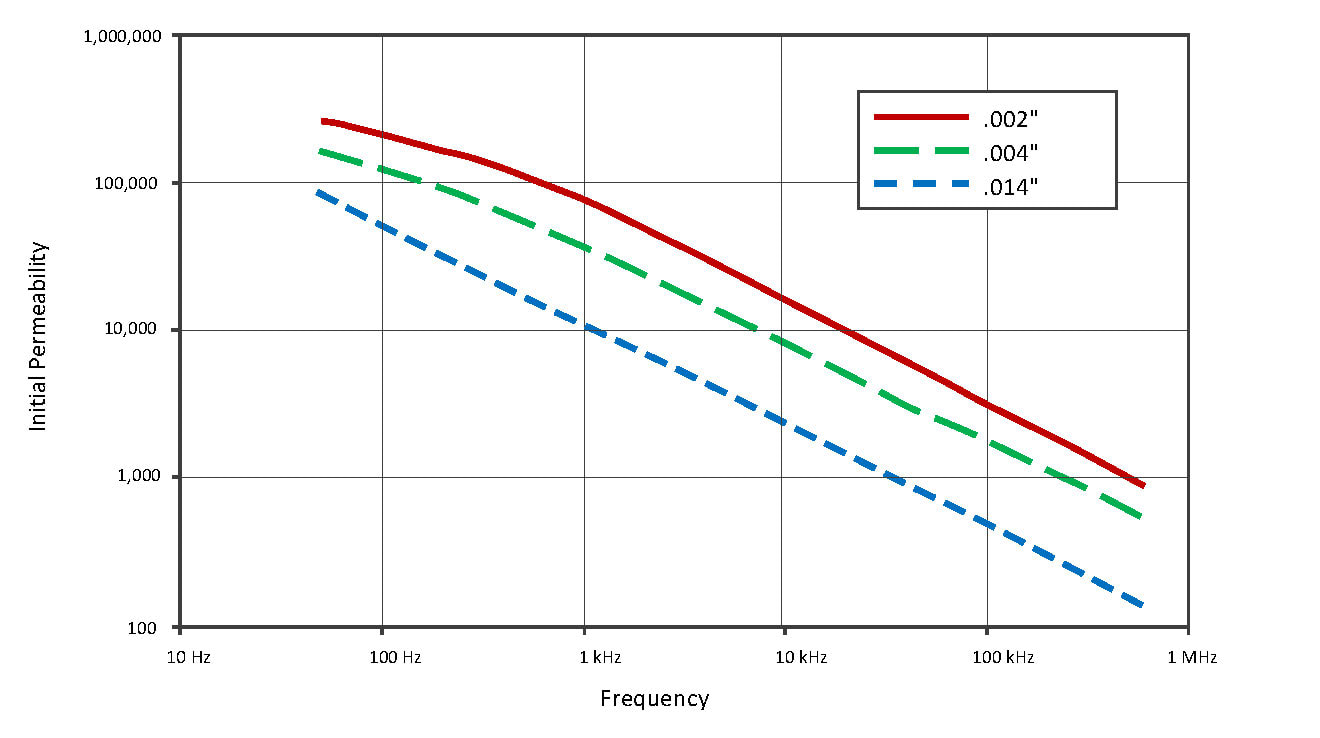

Mumetals provide interference control of H-fields, DC or AC up to 100 kilohertz, and differ fundamentally from RF shielding. The permeability of our shielding alloys begins to reduce drastically near a frequency of 1 kHz. MuMETAL is conductive, so it can potentially shield higher frequency (RF) fields 1-100 kHz, even though they are formulated specifically for low frequency magnetic fields. When both high frequency and low frequency fields are present, our alloys may be most effective if grounded and designed with proper RF shielding practices. Shielding for E-fields and radio frequencies (RF) above 100 kilohertz involves use of high conductivity materials such as Copper, Aluminum or certain conductive coatings.

Approximate ranges are:

Microwave (MW): 300 MHz - 300 GHz

Radio Frequency (RF): 300 Hz - 300 MHz

Extremely Low Frequency (ELF): 30 Hz - 300 Hz

Why must MuMetal be annealed?

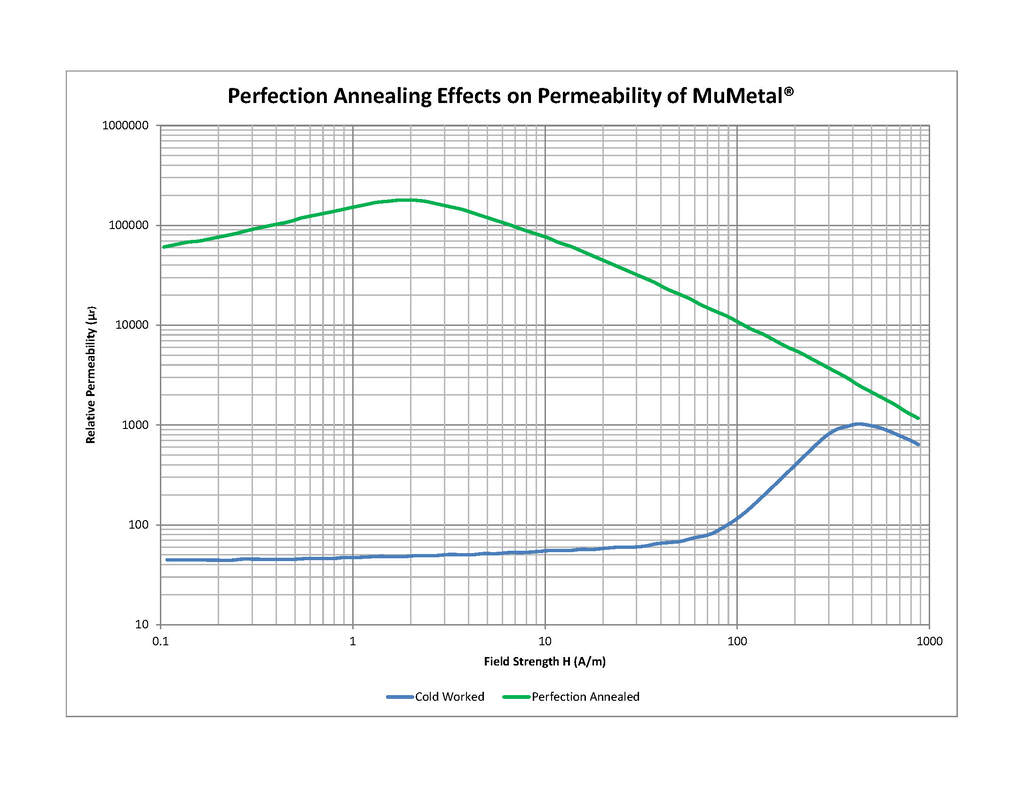

After fabricating, heat treating the mumetal to our Perfection Annealing process is generally required to recrystallize the metal and increase grain size. This final annealing is paramount for the magnetic properties (i.e. permeability) and shield's performance. After annealing, extra care must be taken to avoid dropping or denting as shock will degrade the performance of an annealed shield. When Magnetic Shield Corporation provides MuMetal magnetic shields, they are Perfection Annealed (fully annealed in a controlled dry hydrogen atmosphere furnace with a dew point of <-40 °C). The shields are heated to temperatures >2,000 °F [1100 °C] for a period of time. Proper furnace cooling is critical for the high permeability. This heat treatment increases the magnetic permeability up to 40 times. To insure a shield is annealed properly, we measure attenuation factors (a shield's ability to absorb magnetic energy) in our Quality Control Lab using one of our Helmholtz Coils.

After fabricating, heat treating the mumetal to our Perfection Annealing process is generally required to recrystallize the metal and increase grain size. This final annealing is paramount for the magnetic properties (i.e. permeability) and shield's performance. After annealing, extra care must be taken to avoid dropping or denting as shock will degrade the performance of an annealed shield. When Magnetic Shield Corporation provides MuMetal magnetic shields, they are Perfection Annealed (fully annealed in a controlled dry hydrogen atmosphere furnace with a dew point of <-40 °C). The shields are heated to temperatures >2,000 °F [1100 °C] for a period of time. Proper furnace cooling is critical for the high permeability. This heat treatment increases the magnetic permeability up to 40 times. To insure a shield is annealed properly, we measure attenuation factors (a shield's ability to absorb magnetic energy) in our Quality Control Lab using one of our Helmholtz Coils.